Tubes and pipes are fundamental components in a wide range of industries, from construction and oil and gas to plumbing and manufacturing. Choosing the right type of tube or pipe can significantly impact the efficiency, safety, and longevity of a project. Understanding the characteristics and applications of different tubes and pipes is essential for engineers, contractors, and industry professionals.

In this Blog, we explore seven essential types of tubes and pipes, highlighting their unique features and common uses to help you make informed decisions.

1. Steel Pipes

Steel pipes are among the most durable and widely used types of tubes and pipes. They are known for their strength, resistance to high pressure, and ability to withstand extreme temperatures.

Key Features:

High tensile strength

Resistant to corrosion when galvanized or coated

Suitable for high-pressure applications

Common Applications:

Oil and gas pipelines

Water supply systems

Structural purposes in construction

Steel pipes remain a preferred choice for projects where durability and longevity are non-negotiable.

2. Copper Tubes

Copper tubes are prized for their excellent thermal and electrical conductivity. They are easy to bend and shape, making them ideal for intricate plumbing and HVAC systems.

Key Features:

Excellent corrosion resistance

High thermal conductivity

Flexible and easy to install

Common Applications:

Residential and commercial plumbing

Air conditioning and refrigeration systems

Gas lines

Copper tubes offer a perfect balance of durability and ease of use, making them indispensable in plumbing and HVAC applications.

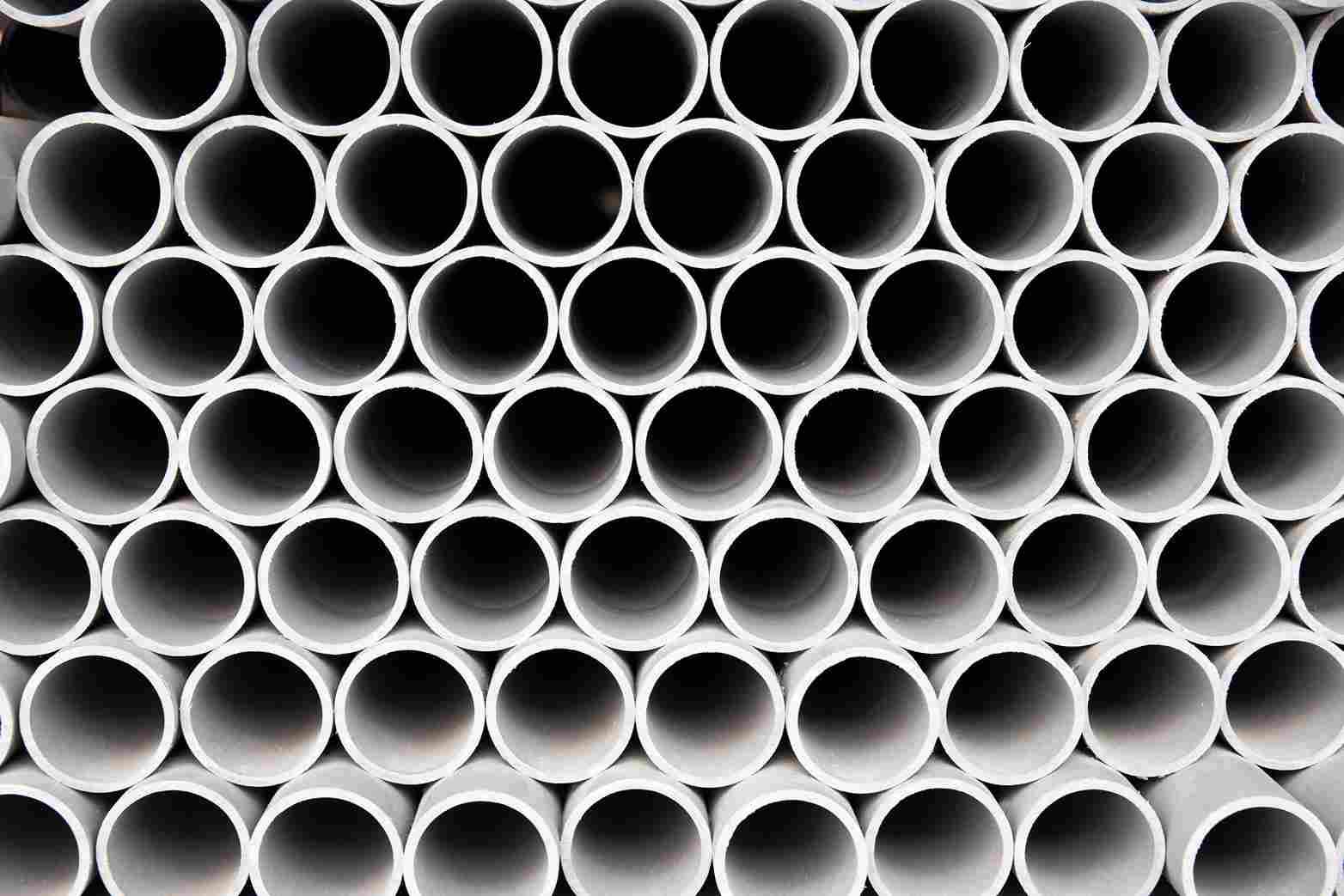

3. PVC Pipes

PVC (Polyvinyl Chloride) pipes are lightweight, cost-effective, and resistant to chemicals and corrosion. Their ease of installation makes them a popular choice for both residential and industrial projects.

Key Features:

Lightweight and durable

Corrosion-resistant

Low maintenance requirements

Common Applications:

Drainage systems

Water supply pipelines

Irrigation systems

PVC pipes are ideal for applications where cost efficiency and chemical resistance are crucial.

4. Stainless Steel Tubes

Stainless steel tubes combine strength with an attractive, corrosion-resistant surface. They are widely used in industries that require hygiene and aesthetic appeal, such as food processing and pharmaceuticals.

Key Features:

High resistance to rust and corrosion

Strong and durable

Attractive polished finish

Common Applications:

Food and beverage processing

Chemical and pharmaceutical industries

Architectural and decorative projects

Stainless steel tubes are a reliable solution when both performance and appearance matter.

5. Galvanized Pipes

Galvanized pipes are steel pipes coated with a layer of zinc to prevent corrosion. They are robust and long-lasting, making them suitable for outdoor and plumbing applications.

Key Features:

Corrosion-resistant due to zinc coating

Durable and strong

Cost-effective for long-term use

Common Applications:

Water supply lines

Outdoor construction projects

Fencing and railing systems

Galvanized pipes provide a balance of affordability and durability, particularly for exposed or high-moisture environments.

6. PEX Tubing

PEX (Cross-linked Polyethylene) tubing has gained popularity in modern plumbing systems due to its flexibility and resistance to scale and chlorine. It is lightweight, easy to install, and ideal for both hot and cold water systems.

Key Features:

Flexible and easy to install

Resistant to scaling and chemical damage

Suitable for hot and cold water applications

Common Applications:

Residential plumbing

Radiant floor heating

Water distribution systems

PEX tubing is revolutionizing plumbing projects with its combination of reliability and installation simplicity.

7. HDPE Pipes

HDPE (High-Density Polyethylene) pipes are known for their strength, flexibility, and resistance to corrosion and chemicals. They are widely used in water, gas, and sewage systems.

Key Features:

Highly durable and flexible

Resistant to corrosion and chemicals

Suitable for long-distance piping

Common Applications:

Water supply networks

Gas distribution pipelines

Sewerage and drainage systems

HDPE pipes are ideal for projects requiring durability, flexibility, and resistance to harsh environmental conditions.

Conclusion

Understanding the different types of tubes and pipes is crucial for making the right choice for any industrial or residential project. Each type—whether steel, copper, PVC, or PEX—offers unique benefits suited to specific applications. Selecting the correct tube or pipe ensures safety, efficiency, and long-term reliability.

For businesses and professionals looking for high-quality materials, partnering with trusted steel suppliers in UAE can streamline procurement, ensure superior quality, and provide expert guidance on the best tubes and pipes for your project.

Write a comment ...